Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

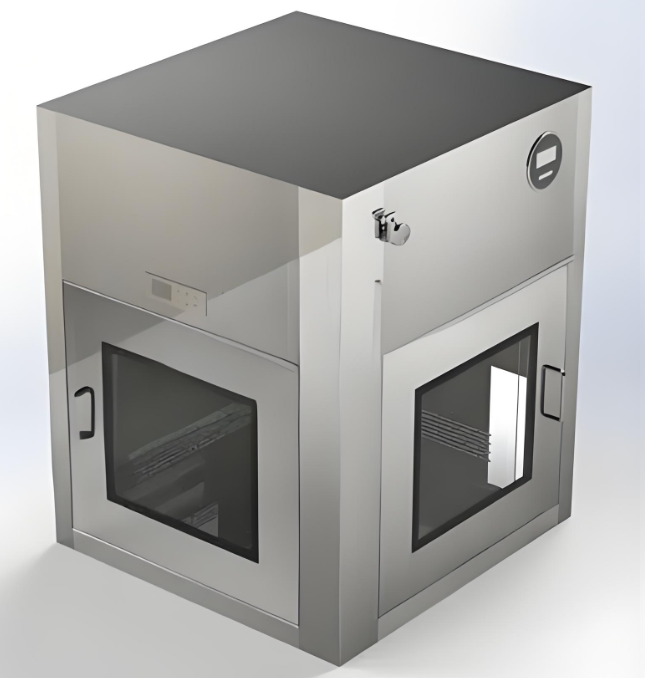

Cleanroom Dynamic Pass Box / GMP Pass Box

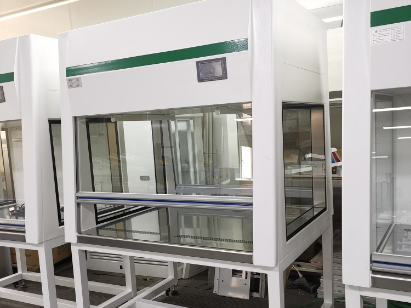

The Cleanroom Dynamic Pass Box / GMP Pass Box is an indispensable piece of equipment for maintaining strict cleanliness and contamination control within cleanroom environments, particularly in industries such as biopharmaceuticals, semiconductors, and medical device manufacturing. This advanced transfer system is designed to facilitate the safe and efficient transfer of materials between different cleanliness levels or between cleanrooms without compromising the integrity of the clean environment.

Equipped with high-efficiency particulate air (HEPA) filters and often integrated with laminar flow technology, the Cleanroom Dynamic Pass Box / GMP Pass Box ensures that the air within the box is continuously filtered and recirculated, creating a localized clean environment. The interlocking door design prevents simultaneous opening of both doors, minimizing the risk of contamination from the external environment.

Our pass boxes are constructed from high-quality stainless steel, providing a durable and corrosion-resistant surface that is easy to clean and maintain. Customizable options, such as UV sterilization lights, timers, and intercom systems, further enhance the functionality and convenience of these units.

Whether you need to transfer sensitive materials between cleanrooms, or ensure the sterile transfer of medical devices and components, the Cleanroom Dynamic Pass Box / GMP Pass Box offers a reliable and effective solution. With its robust construction, advanced filtration technology, and customizable features, it is an essential tool for maintaining cleanliness and contamination control in high-stakes environments.

The Cleanroom Dynamic Pass Box / GMP Pass Box is a state-of-the-art equipment designed to maintain the cleanliness and integrity of critical controlled environments during material transfers. Also known as Active Pass Boxes or Dynamic Floor Laminar Hatches, these units create an inflated barrier to provide comprehensive protection against contaminants.

Key Features:

- Dynamic Airflow: Provides an effective air barrier to prevent contaminants from entering the critical environment.

- Vertical Purging: Allows for tracing and removal of potential contaminants post-material transfer.

- Recirculating Airflow System: Ensures efficient and consistent air quality control.

- On-board Fans: Powerful fans support the dynamic airflow and maintain optimal conditions.

- No External Ducting Required: Simplifies installation and reduces maintenance.

- Durable Construction: High-quality materials ensure longevity and reliable performance.

- Stainless Steel Construction: Easy to clean with rounded/coved corners.

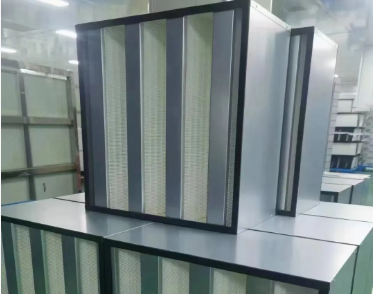

- HEPA (H14) Filtration: Ensures high filtration efficiency and ISO Class 5/Grade A environment.

- G4 Pre-filters: Extend the lifespan of the main filter.

- User-friendly Controls: Simple switches or advanced DSX microprocessor control for easy operation.

- Indicator Lights: Red/green lights signal door status for enhanced user awareness.

- Emergency Stop Buttons: Conveniently located on both sides for quick access.

- Tempered Glass Viewing Window: Allows easy monitoring of the internal chamber.

- Electromagnetic Interlocking Doors: Prevent simultaneous opening of both doors for safety.

- Perforated Grille System: Promotes full downflow circulation in critical areas.

- PAO Injection Port: For HEPA filter integrity testing.

- Differential Pressure Monitoring: Magnehelic gauge or digital display with filter load alarm capabilities.

Applications:

- Manufacturing Facilities: Ensures materials and equipment transferred into cleanrooms do not compromise aseptic conditions.

- Pharmaceutical Industry: Vital for maintaining cleanliness standards where even slight contamination can lead to quality or safety issues.

- Cleanroom and Controlled Environments: Facilitates material transfer while minimizing contamination risk.

- cGMP Facilities: Adheres to strict regulations by preventing contaminant ingress.

- Nanotechnology: Safeguards process and research integrity in precision-focused industries.

- Semiconductor Industry: Prevents particulate contamination impacting fabrication processes.

- Space Industry: Maintains cleanliness of equipment and materials crucial for mission success.

- Automotive Industry: Ensures cleanliness in manufacturing processes, especially for electronic components and advanced technology vehicles.

Overall, the Cleanroom Dynamic Pass Box / GMP Pass Box is a versatile solution tailored to meet the stringent requirements of various industries, ensuring contamination-free material transfers in critical controlled environments.

All products can be customized as actual requirement

Product Showcase · Excellent Quality

|

|

|

| Laser cutting | CNC bending Center | CNC Punch Press Punching |

|

|

|

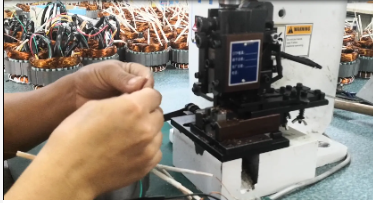

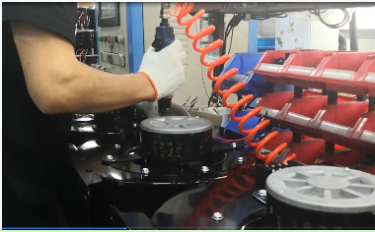

| CNC bending | DSX Motor production | Motor production |

|

|

|

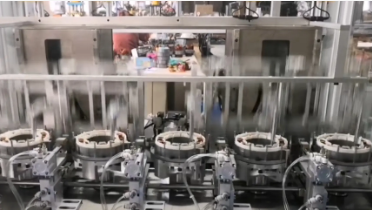

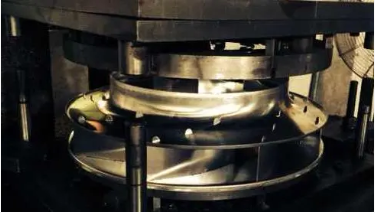

| Motor production | Produce impeller | Balancing the impeller |

|

|

|

| Motor test | Blower production | Blower testing |

|

|

|

| Chemical filters Production | Chemical filters Production | Chemical filters Production |

|

|

|

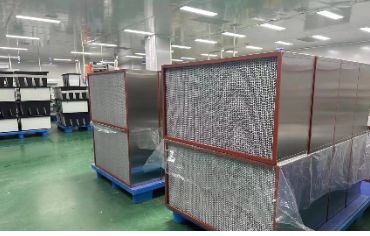

| HEPA filter workshop | Special filter Production | W-type filter production |

|

|

|

| High temperature filter | Rivet workshop | Laser welding |

|

|

|

| Welding workshop | Welding workshop | Cutting of profiles |

|

|

|

| FFU assembly | FFU assembly | FFU assembly |

|

|

|

| Air shower room assembly | Clean bench production workshop | Clean bench production workshop |

|

|

|

| Pass boxes production workshop | HEPA BOXES production workshop | HEPA Boxes test |

|

|

|

| EFU production | Warehouse | Shipment |

Cleanroom Dynamic Pass Box / GMP Pass Box FAQ

Q1: What are Cleanroom Dynamic Pass Boxes and GMP Pass Boxes?

A: Cleanroom Dynamic Pass Boxes and GMP Pass Boxes are auxiliary equipment used for material transfer within cleanrooms. They are primarily designed to reduce the frequency of cleanroom door openings, thereby maintaining the cleanliness of the internal environment. Cleanroom Dynamic Pass Boxes often come equipped with HEPA filters and fans, creating a locally high-cleanliness environment, while GMP Pass Boxes focus more on meeting the stringent cleanliness requirements of Good Manufacturing Practices (GMP).

Q2: What materials and structures are they made of?

A: These pass boxes typically utilize high-quality stainless steel (such as SUS304), known for its corrosion resistance and ease of cleaning. Structurally, they include two interlocking doors to ensure that both doors cannot be opened simultaneously during material transfer, thereby preventing air contamination. Customizations, such as timers, intercoms, and sterilization lamps, can also be added based on customer needs.

Q3: How do they work?

A: The working principle of Cleanroom Dynamic Pass Boxes and GMP Pass Boxes is based on an interlocking door system and HEPA filtration technology. When materials need to be transferred from one clean area to another or from a clean area to a non-clean area, operators can open one side's door, place the materials inside the pass box, and then close that door. At this point, the other side's door can be opened to retrieve the materials. The HEPA filter is used to filter out particles and bacteria in the air, ensuring cleanliness during the transfer process.

Q4: What are their application scenarios?

A: These pass boxes are widely used in industries requiring high-cleanliness environments, such as biopharmaceuticals, semiconductors, and food processing. In the biopharmaceutical industry, GMP Pass Boxes are indispensable equipment for ensuring sterility and cleanliness during production processes.

Q5: How should they be maintained and serviced?

A: Regular cleaning and inspection are crucial for maintaining the performance of pass boxes. Suitable cleaning agents and tools should be used for cleaning, avoiding chemicals that may damage the material. At the same time, the status of the filters should be regularly checked, and clogged or damaged filters should be replaced promptly.

Deshengxin: Crafting Efficient and Clean GMP Pass Boxes to Propel the Biopharmaceutical Industry

In the biopharmaceutical industry, which demands extremely high cleanliness, GMP Pass Boxes serve as vital auxiliary equipment within cleanrooms. Their performance and quality directly affect product quality and production efficiency. Deshengxin, a company specializing in the research and development of cleanroom equipment, is dedicated to providing customers with efficient and reliable GMP Pass Box solutions.

1. Exquisite Craftsmanship and Superior Quality

Deshengxin's GMP Pass Boxes are crafted from high-quality stainless steel, undergoing precise processing and stringent inspections to ensure corrosion resistance and ease of cleaning. Furthermore, we adopt advanced manufacturing processes and quality control systems to ensure that every GMP Pass Box meets customers' expectations for cleanliness and performance.

2. Customized Designs to Meet Diverse Needs

We understand that different customers have varying needs for GMP Pass Boxes. Therefore, Deshengxin offers customized design services, adjusting dimensions, materials, accessories, and other aspects based on customers' specific requirements, ensuring that the product seamlessly integrates into their cleanroom environment.

3. Efficient Filtration Technology to Ensure Cleanliness

Deshengxin's GMP Pass Boxes are equipped with HEPA filters, effectively filtering out airborne particles and bacteria, ensuring cleanliness during the transfer process. Additionally, we provide regular maintenance and servicing to ensure the continued efficient operation of the filters.

4. Professional Services for a Hassle-Free Experience

Our dedicated sales and after-sales service teams provide comprehensive services, ranging from consultation, selection, installation, to maintenance. No matter what issues customers face, we can respond quickly and provide effective solutions.

In summary, Deshengxin's GMP Pass Boxes, with their exquisite craftsmanship, superior quality, customized designs, efficient filtration technology, and professional services, have earned the trust and praise of numerous customers. In future developments, we will continue to adhere to the principle of "Quality First, Customer Supreme," providing the biopharmaceutical industry with even more efficient and reliable cleanroom equipment solutions.